Quality Information About Molds and Tooling for Die Casting

Die casting tooling quality or die casting mold quality is relative to the customer needs. For more tooling information or die casting mold pricing contact us: sales@tile-molds.com

Die Casting Tooling Quality is measured in two ways. https://www.tile-molds.com

How is the accuracy of the tool to meet the die casting part blueprint dimensions. Some inexperienced toolmakers, foreign or domestic, do not understand the engineering need for die casting part draft. All die casting parts need draft to eject from the die cast mold. Some moldmakers cannot calculate die casting alloy or material shrinkage. All die casting alloys have process shrinkage. Not all die casting materials shrink the same.

Also, the more experienced of the toolmakers or moldmakers will use “steel Safe” measures to meet tolerances on the die casting part blueprint. We want to remove more steel to meet dimensions, not weld the steel. Welding sometimes reduces “Die Life”

Some customers only need a few hundred parts in the product lifetime. Others need more than 100,000 die casting parts a year. Die Life is a measurement of how many parts the die casting tool will make that are acceptable to the customer. Sometimes I get this question “how long will my die casting tool make acceptable parts?” This is both an easy question and difficult question. he easy answer is, a new class A die casting tool will make about 100,000 acceptable aluminum die casting parts and about 200,000 zinc die casting parts. If the die casting part is thicker or heavier, the quantity could be less and if the part is smaller the quantity could be more. Many customers need fewer than 100,000 parts. Also, as noted before, some die casting materials wear the tooling more than other materials. The first areas of wear are the areas where the molten material enters the tool. The second areas are around the parting line.

Here are the order of die casting tools that have greater die life to the least die life:

- Complete Die Casting Mold

- Unit Die Tooling

- Die Casting Tooling Inserts

- Die Casting Family Mold

Regular maintenance items in the die casting mold are:

Email us if you have other questions or if you want die casting mold prices. If you have a die casting mold or tool that needs repair, we can help you. If you have a die that was made somewhere else, we can make your die casting parts.

Tile Molds Die Casting Molds

Contact or Pricing for die casting molds: sales@tile-molds.com

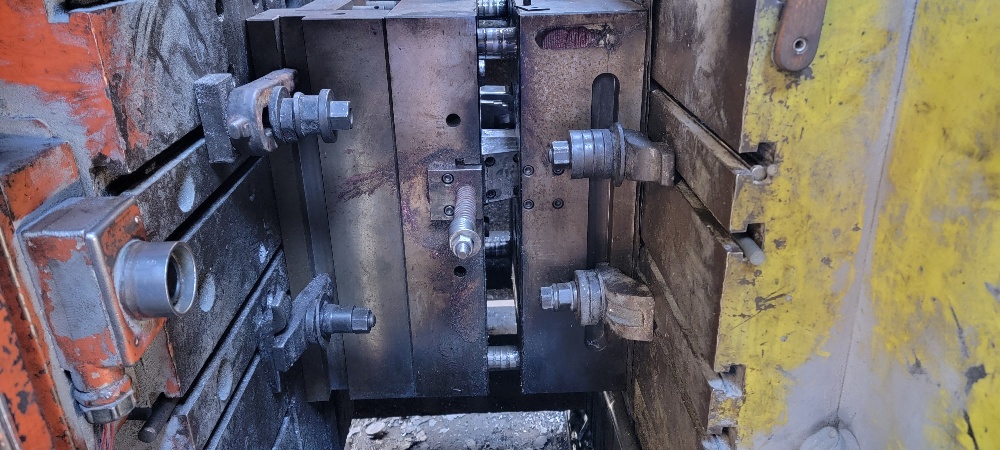

About Tooling – Tooling Quality – FAQs – Tooling Photos

Die Casting Molds – Privacy – Site Map – Die Casting Molds Blog

Permalink: https://www.tile-molds.com/blog/tooling-quality-for-die-casting-molds/