Die Casting Tooling and Die Design: The design of the die is critical. It must account for the metal alloy material flow, cooling, and ease of part ejection. The right design minimizes defects, reduces cycle time, and ensures the longevity of the tool. sales@tile-molds.com

Die Casting Tooling Molds Quality Selection: Dies are often made from high-grade steels, such as H13 or P20, which are known for their strength and thermal resistance. These materials withstand the high pressures and temperatures involved in the casting process, ensuring consistent part quality.

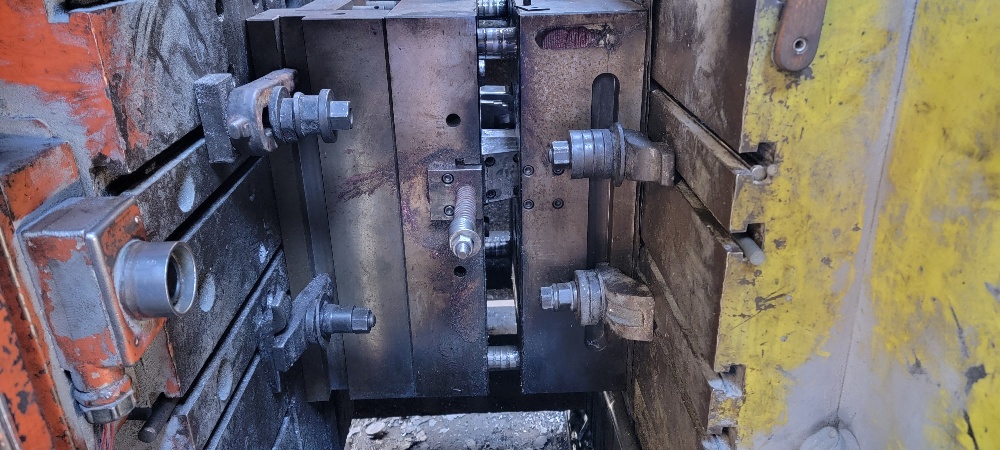

Molds and Tooling Maintenance: Regular die maintenance is essential for ensuring the longevity and performance of the die. This includes cleaning, lubricating, and repairing worn-out components. Without proper care, tooling can lead to poor-quality parts and costly downtime.

Cooling System: Proper cooling channels within the die are crucial for ensuring quick solidification of the metal and reducing cycle times. Optimizing the cooling system can significantly enhance the efficiency of the die casting process.

Ejection System (more die casting tooling terms): An effective ejection system ensures that parts are removed from the die without damage. This can involve mechanical or hydraulic ejectors, or even automated systems, depending on the complexity of the part. sales@tile-molds.com

Permalink: https://www.tile-molds.com/blog/key-elements-of-die-casting-molds-and-tooling/