Concrete Roof Tiles

Concrete roof tiles first came about in the 19th century. Sand, water and cement were mixed to produce the first concrete roofs. In the early 1900’s, concrete tiles became more stylish. Color pigments were added to them so that they may look like clay roofs. As time went by, modern technology has improved the appearance and quality of concrete roofs, and companies continue to manufacture these roofs that last a lifetime. Many houses that first used concrete roofs actually have their houses standing still up to this date. That’s because of the durability of concrete. They can sustain winds that are over 125 mph, while other roof types would have been stripped away at this speed of wind.

In addition, they are Class A fire resistant and are not attractive to termites and moss as well. Even earthquakes cannot easily put down a roof made of concrete. The key here is properly installing the concrete roof, such that it follows the building code standards. Many homeowners also choose this type of roof because it doesn’t require much maintenance and repair. Although it is a bit costly, the performance it does to protect your home is clearly outstanding. This is why concrete roof tiles are popular everywhere.

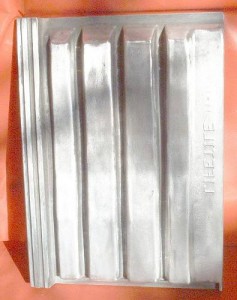

<p>Design and Production of great Quality Concrete Roofing Tile Molds at great Prices. <a href=”http://www.tile-molds.com/design.html”

title=”Design and Price for Roofing Tile Trim Molds”>Price for Roofing Tile Trim Molds</a>

<br> Look at our <a href=”http://www.tile-molds.com/blog/” title=”tile molds blog”>tile molds blog</a> for more information about

<P><a href=”http://www.tile-molds.com” title=”Aluminum Tile Mold Plates for Concrete Roofing” target=”_blank”>

<img border=”0″ src=”http://www.tile-molds.com/images/header1x1.gif”

alt=”Aluminum Tile Mold Plates for Concrete Roofing” width=”468″ height=”60″></a>

<p>Email us for a price on roof tile molds <a class=”regtext” href=”mailto:sales@tile-molds.com”><font color=”#ff0000″>sales@tile-molds.com</font></a>