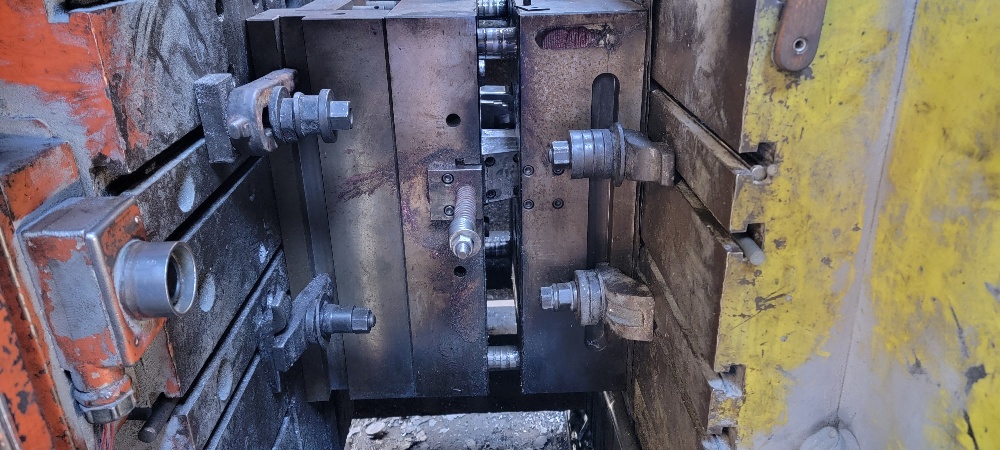

The use of Die Casting DME Tooling is very common in at Kinetic Die Casting Company and die casting companies world-wide. DME’s are enhancing tooling efficiency and provide precision in the die casting metal parts production. sales@tile-molds.com

In the always evolving world of die casting, achieving precision and efficiency in manufacturing processes is critical for maintaining a competitive edge. One key component in this effort is DME Tooling, which stands as a pillar in the industry for enhancing die casting operations. DME has long been synonymous with high-quality die casting tooling, durable, and precise tooling solutions, trusted by manufacturers worldwide to ensure consistent and high-performance results. In this newsletter, we will explore how DME tooling is driving innovation, improving productivity, and ensuring product quality in die casting.

Permalink: https://www.tile-molds.com/blog/introduction-of-dme-tooling-for-die-casting/